Neodymium magnet (Nd-Fe-B) composed of neodymium, iron, boron and a few transition metals are available in different Grades which span a wide range of properties and application requirements. They can be made into different shapes, such as disc,block, ring, and arc. As well some special and complex shapes can be customized to meet our customer specific application requirements. With improvement of neodymium magnet properties, they have been used in high performance motors, wind generators, meters, sensors, sound device, magnetic suspension system, magnetic transmission machine and magnetic imaging for medical and other high-tech fields.

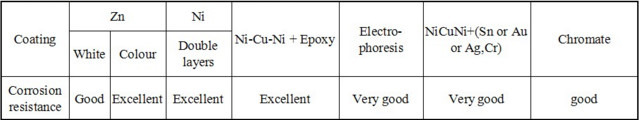

Neodymium magnets are highly susceptible to corrosion. To protect neodymium magnet from corrosion, it is usually preferable for them to be coated. There are a variety of options for coatings for example, zinc, Nickel, copper, epoxy, silver and gold, but nickel is the most common and usually preferred. The nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again, which makes magnets much more durable than the common single nickel plated magnets.

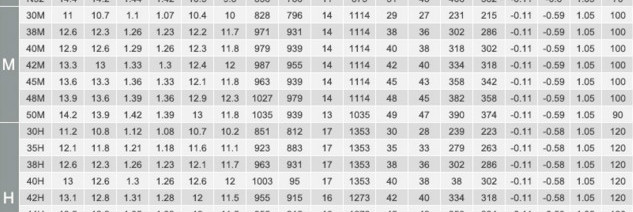

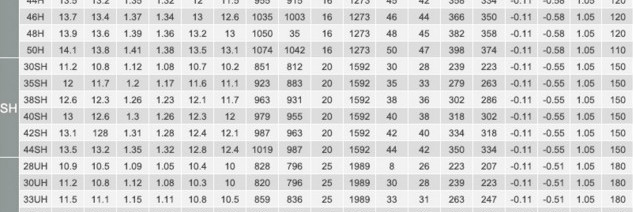

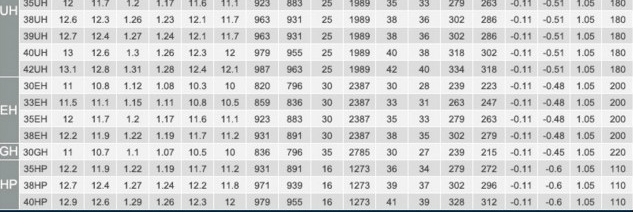

Magnetic Properties of Sintered NdFeB

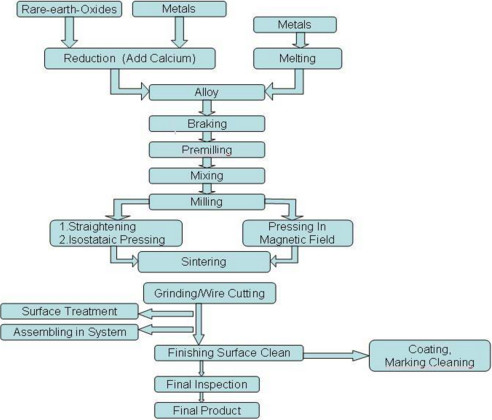

Flow Chart of NdFeB

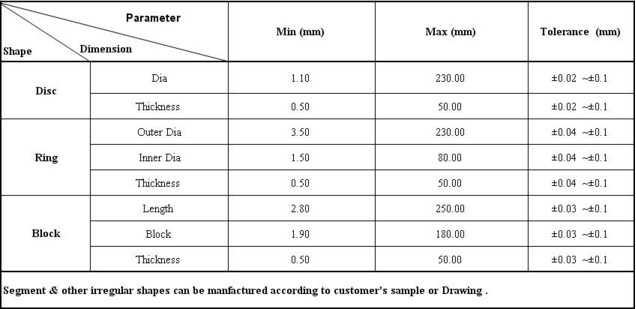

Dimension Range

Coating of NdFeB